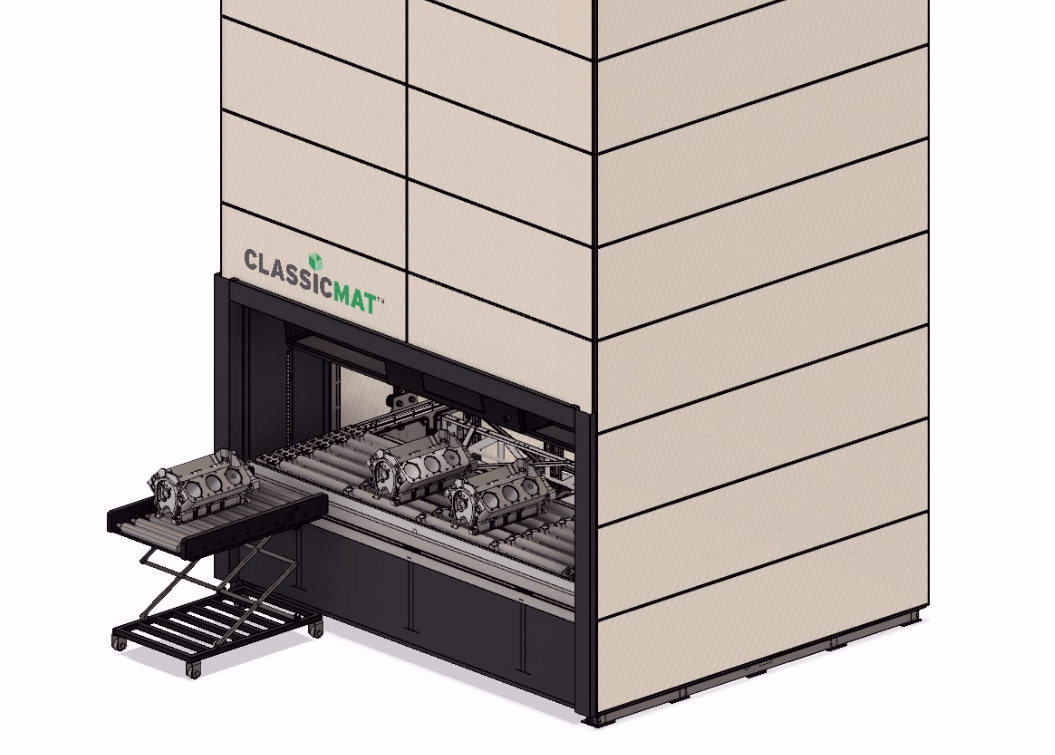

Our automated vertical carousels store vertically to make use of overhead space and to maximize storage density.

Based on the Ferris Wheel principal, vertical carousels store inventory on a series of carriers that remain level while rotating within the machine, much like the cars of a Ferris Wheel. Carriers can be equipped with shelves, drawers, totes, dividers and specialized racks to accommodate any manner of specialized storage needs.

Our industrial vertical carousels are developed to optimize storage space and increase productivity in warehouses, factories, machine shops, and distribution centers. Today, options include a variety of shelves, bins, drawers and specialized holder to store just about anything.

Advantages of our industrial vertical carousels:

More Floor Space

Storing vertically saves valuable floor space, allowing users to store more within the space they already have, eliminating the need for expansion or relocation. Space can also be freed up for other uses within the same facility.

Control of Inventory

Microprocessor-based controllers and advanced inventory management software allows user to gain better control over their inventory for improved accuracy, fewer errors, and lower costs.

Increased Productivity

Items are brought to the user, eliminating the time spent walking rows of shelving to locate and retrieve items, for greater speed and accuracy.

Improved Ergonomics

Items are delivered at an ergonomically-correct access point, eliminating climbing and stooping as well as carrying heavy and bulky items.

Enhanced Security

Enclosed storage protects and secures inventory. Locking doors and user authorization requirements prevent unauthorized access.